WOODSTORE

Nature-Based Carbon Capture and Storage

The increasing concentration of CO₂ in the atmosphere, caused by the burning of coal, oil, and gas over the past 100 years, is the main driver of climate change on Earth.

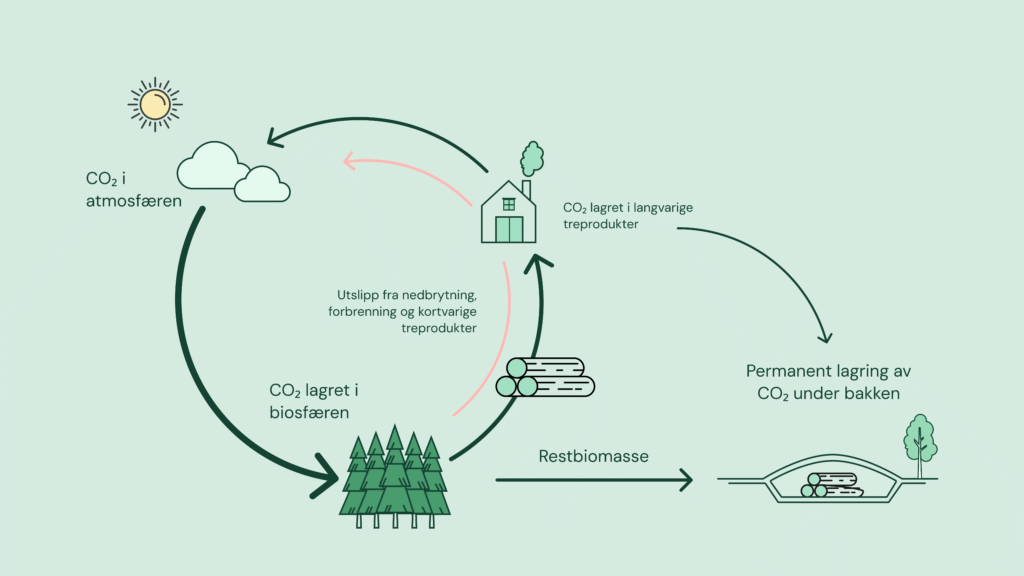

Photosynthesis on land and in the oceans is by far the world’s largest and most cost-effective CO₂ vacuum. Every spring and summer, the world’s forests convert enormous amounts of CO₂ from the air into carbon stored in wood and leaves. But each autumn and winter, some of this carbon quickly returns to CO₂ as the leaves fall and decompose. When trees die—whether naturally or through logging—most of the carbon stored in roots, trunks, and branches returns to the atmosphere as CO₂ through decay or combustion. Some of it happens quickly, while some carbon remains bound in building materials before eventually becoming CO₂ again when those materials are used for energy recovery. Except for the portion of carbon that is permanently stored and accumulated in the forest soil, the life cycle of a tree is essentially a zero-sum game where trees take up and release roughly equal amounts of CO₂.

ZERO-SUM CYCLE

Nature-based carbon capture and storage is about breaking this zero-sum cycle by preventing (fully or partially) the carbon in trees from returning to the atmosphere as CO₂ at the end of their life.

When a new tree grows to replace the one that died, you have effectively created a net-negative emissions technology (NET). The world will have enormous demand for NET technologies—both nature-based and others—over the coming decades to compensate for insufficient and delayed greenhouse gas reductions, which alone won’t be enough to avoid catastrophic climate change.

STORING CARBON

The storage of the captured carbon in the dead biomass can be done in several ways.

01 Biomass Power Plant with CCS

The biomass is used as fuel in a thermal power plant where the CO₂ is captured from the exhaust gases, compressed, and then transported by truck and/or ship to a permanent storage site. There, it is injected into porous rock formations deep underground. The Norwegian moon landing project Langskip is doing exactly this. In principle, this is an elegant method that also allows us to utilize the energy in the biomass, but in practice, the potential of this method is very uncertain. The costs associated with capture, compression, transport, and storage currently amount to several thousand Norwegian kroner per ton of CO₂.

02 Biochar

Biochar is produced through pyrolysis, where wood biomass is burned with limited oxygen supply. The carbon after combustion is roughly divided as follows: biochar (50%), bio-oil (30%), and CO₂ (20%). The biochar is very stable and can potentially store carbon intact for hundreds of thousands of years. The challenges with this method are that only up to 50% of the carbon is stored, and the costs involved are also significant.

03 CSWB (Carbon Sequestration via Wood Burial)

CSWB is a method where biomass is stored directly underground in a way that prevents it from decomposing into CO₂ (aerobic decomposition caused by fungi) or methane (anaerobic decomposition caused by bacteria). Many researchers and forestry experts are skeptical about whether it is practically possible to create such stable storage chambers where biomass remains intact for hundreds or even thousands of years.

Sylva has strong confidence in CSWB and, with its own developed methods called WoodStore, is close to proving that biomass can be stored intact for thousands of years using simple and cost-effective techniques.

ABOUT WOODSTORE

This is Woodstore

ABOUT WOODSTORE

WoodStore is, in short, Sylva’s method for long-term storage of clean residual biomass from forestry and other sources.

This is done in stable underground storage chambers without oxygen access to prevent natural decomposition. We call these storage chambers Carbon ChambersThe carbon chambers are typically built in a distributed and local manner to minimize the need for transportation.

CLEAN RESIDUAL BIOMASS

Clean residual wood biomass can come from many sources.

- Residual biomass after harvesting: branches and tops (GROT), as well as possibly roots.

- Residual biomass from sawmills.

- Biomass after thinning in the forest.

- Low-quality trees, diseased trees, and windfall timber.

- Sawmill remnants.

- Reclaimed wood from demolished buildings.

- Clearing of vegetation along roads and railways, as well as under power lines.

Use of Residual Biomass

In Norway, residual biomass is currently utilized to a small extent. Sawmill remnants are widely used for wood chip production (for central heating), and demolition materials from buildings go to energy recovery. Some residual biomass from logging is used to make biofuel. However, most of it is left on the logging site and turns into new CO2 in the atmosphere within 5-15 years. The potential of WoodStore as a carbon capture and storage method is formidable.

Can We Utilize All Residual Biomass?

Deadwood is the energy source and habitat for countless plants, animals, and fungi. Ecosystems depend on a sufficient amount of deadwood. For this reason, many foresters believe that all residual biomass from logging should be left behind on the logging site. However, to combat climate change (which is also crucial for biodiversity), we must find good compromises. We believe Sylva's Climate Forest and Nature Forest concept will solve this dilemma.

BENEFITS

Simple

Building carbon chambers and harvesting biomass are relatively simple operations that do not require an industrial facility or access to electricity.

Effective

Biomass stores carbon densely. For every tonne of carbon stored with Woodstore, only a few dozen kilos of associated emissions are generated.

Scaleable

It is scalable and accessible to many.

Operative

It’s already up and running because the technology exists.

Use of Resources

By using leftover biomass that would otherwise rot or be burned, we instead create carbon credits. This generates greater value by utilizing a resource that has so far been underused in Norway.

Profitable

Carbon credits produced at relatively low cost compared to other carbon capture and storage methods.

WHY AND HOW

When biomass naturally decomposes through oxygen-breathing fungi, CO₂ is released. By removing the oxygen, the fungi cannot survive, and the decomposition process stops.

Wood has the property of biomass recalcitrance, making it resistant to decomposition by anaerobic bacteria. Methane is produced by anaerobic bacteria during decomposition processes. Research shows that methane emissions from waste facilities mainly come from anaerobic breakdown of leaves, grass, and food waste, and to a much lesser extent from wood materials. This means that wood stored without oxygen access represents a very stable form of carbon storage. The question is: how stable?

Step 1

Biomass harvesting

Residual biomass, including roots and logging residues (grot), is harvested from the logging site. When roots are also removed, this simultaneously provides effective soil preparation for replanting. Logging residues often make it difficult for people and animals to move around the area. By collecting the residues, more space is freed up on the ground for new plants and easier access. This leads to faster tree growth and a quicker return to a harvestable forest that continues to capture CO2. An added benefit is that the logging site becomes more aesthetically pleasing and can be used as a recreational area.

Step 2

Placement of Carbon Chambers

The placement of carbon chambers should be carefully planned. Generally, they are located near or directly on the logging site to allow easy access and minimize transportation of biomass. When larger quantities of clean residual biomass become available from multiple sources, it may be practical to establish larger, more centralized carbon chambers. It is advantageous to place the carbon chambers in areas with easy access to clay, as this makes transportation more cost-effective.

A Woodstore carbon chamber doesn’t take up much space but will cause some terrain elevation of a few meters when completed. This should be viewed as an opportunity rather than a problem. Here are two examples of how Sylva plans to establish its first Woodstore chambers:

- In many areas of cultivated land, drainage can be a challenge—especially where the terrain has larger “depressions.” By establishing carbon chambers in such locations, the terrain is raised and drainage problems are resolved. About 50 cm below the topsoil, in areas lower than 100 meters above sea level in Eastern Norway, you’ll find blue clay. This locally sourced blue clay is ideal for sealing the chamber. After the clay cover is in place, the topsoil is returned.

- At Hauger Farm, there are many power lines. The areas beneath them are regularly cleared of trees and brush, which incurs significant costs for the line owners, Statnett and Elvia. Sylva plans to offer Statnett and Elvia a partnership where Sylva takes care of the clearing and establishes Woodstore carbon chambers under the power lines. On top, new pasture and/or young tree production for the Climate Forest will be developed.

Step 3

Building Carbon Chambers

Sylva is exploring two alternative Woodstore methods:

- Woodstore 1: The chamber filled with shredded biomass is covered with a thick layer of clay, followed by topsoil.

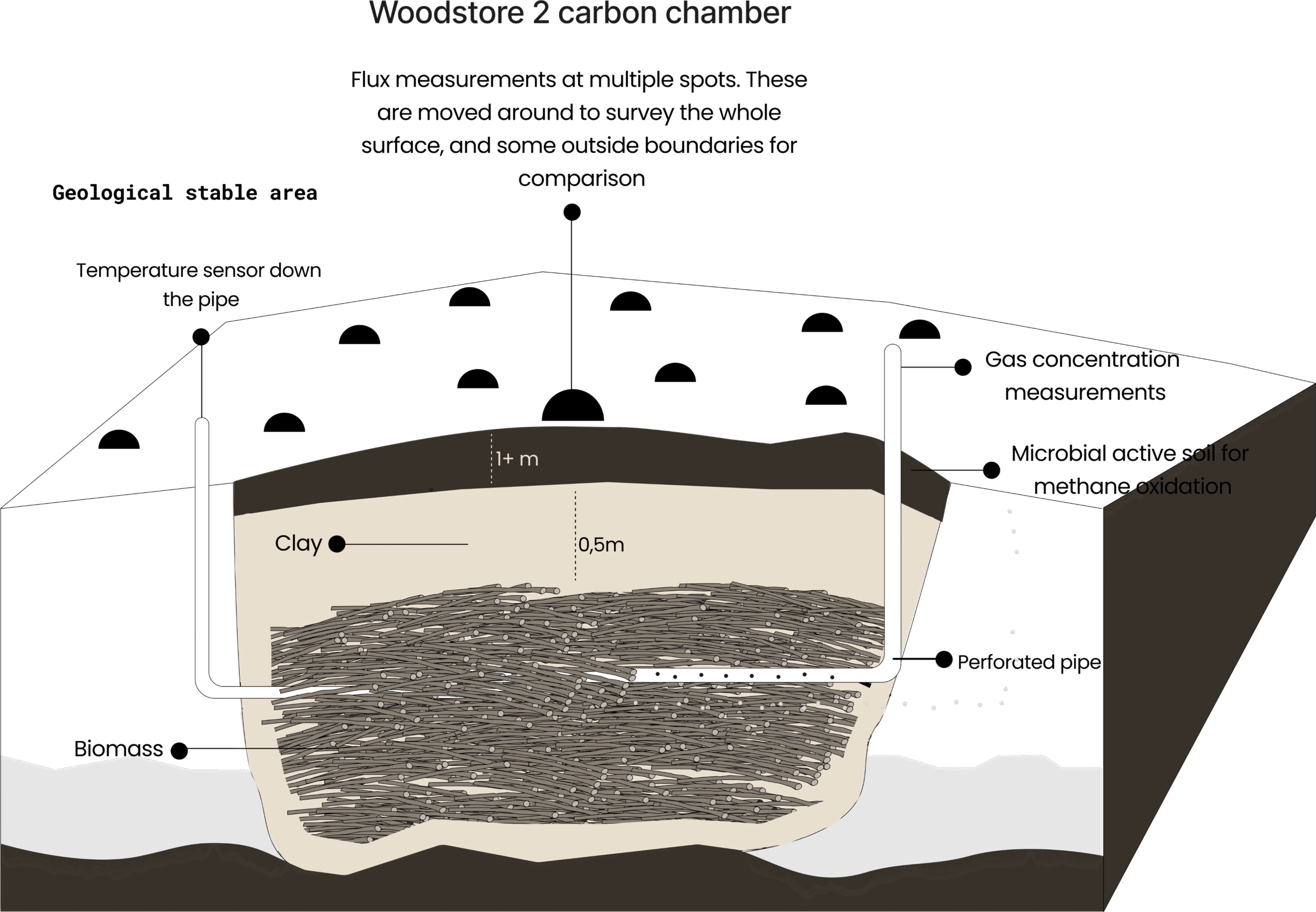

- Woodstore 2: Same as WoodStore 1, but where all the cavities in the biomass are also filled with clay.

The advantage of Woodstore 1 is that it is the cheapest, while Woodstore 2 is the safest.

Step 4

Monitoring

2025 will be an important year to prove and document the Woodstore 1 method. We need measurable data showing how effectively the chamber works. Therefore, gas concentration measurements inside the chamber and gas flux measurements on the surface will be conducted regularly over an extended period. Perforated pipes will be installed in direct contact with the biomass. The risk is that greenhouse gases, especially CO2 and methane, may be produced due to unforeseen decomposition of the biomass, and this must be closely monitored.

In addition to gas concentration, temperature and humidity must also be measured. This allows us to compare conditions and concentrations both inside and above the chamber. Once sufficient data has been collected, we can calculate decomposition curves and estimate total emissions over a period of 100 years or more.

Step 5

Certification and Sale of Carbon Credits

If the project succeeds, Woodstore will be recognized as a NET (Negative Emission Technology) method for boreal forests.

As part of the project, there will be emissions from machinery use and disturbances in the harvest area. There are also estimated emissions from the natural decomposition of biomass. If the total emissions are lower — or significantly lower — than the amount of carbon stored in the biomass, Woodstore will be considered net-negative and thus qualify as a NET (Negative Emission Technology) method. Sylva will then be able to certify the carbon storage and offer carbon credits from the Woodstore project. These credits can be purchased by companies and organizations seeking to offset their carbon footprint. The carbon credits must be verified through a rigorous certification process by independent third parties.

WOODSTORE 1

Sylva established its first Woodstore 1 in 2023, storing 600 tons of CO₂, and has initiated quality assurance and monitoring.

Before and after

The image on the left shows the biomass in the carbon chamber before it was covered with clay.

The image on the right shows Woodstore 1 has been covered with soil, and fruit trees have been planted.

The biggest uncertainty with Woodstore 1 is that air pockets inside the biomass allow pressure changes to affect the chamber. High pressure weather can push air into the chamber, while low pressure systems can draw gases out. This breathing effect means there will always be some oxygen present around the biomass. So far, we have measured an average oxygen concentration of about 3 percent. Throughout 2025, we will investigate how this level of oxygen affects the breakdown of biomass. Another key question is how much methane is being produced. Methane is 28 times more powerful as a greenhouse gas than carbon dioxide, so even small emissions could be a problem. Some of the methane is likely broken down by methane eating bacteria in the soil layer above the chamber, but the question is, how much?

WOODSTORE 2

The first Woodstore 2 will be built in 2026.

If we have some uncertainties about the Woodstore 1 method, we are much more confident that Woodstore 2 will work. It is well known that wood pulp can remain intact for thousands of years as long as it is kept oxygen-free. Such conditions are found, for example, in wet peat bogs.

Before and after

The photos below were taken from a trench dug across a field at Hauger Gård in 2024. They show apparently intact pieces of wood embedded in clay about 1 meter below ground level.

The site where the photos were taken is at 75 meters above sea level and was submerged under water until about 10,000 years ago. Our only reasonable explanation for the pieces of wood found in the clay is that they must have floated in the water more than 10,000 years ago, then rotted, sank to the bottom, and were slowly covered by clay particles. Several of the wood samples have been dated using the C14 method, with preliminary results indicating that the wood was alive between 2,000 and 5,000 years ago. This discrepancy is likely due to measurement uncertainty. Regardless, the age is significant enough to strongly suggest that Woodstore 2 could work very well.

LEARN MORE

The difference between voluntary carbon credits and carbon allowances

VOLUNTARY CARBON CREDITS

Companies that want to take responsibility for their climate footprint can purchase voluntary carbon credits from projects that reduce or remove carbon from the atmosphere and store it, such as NET technologies like Woodstore.

CARBON CREDITS

A carbon allowance is a permit that grants the right to emit a specific amount of greenhouse gases under government regulations on carbon emissions. This applies to emission types covered by the allowance system.

Our partners

FoU COLLABORATION

NIBIO

NIBIO (Norwegian Institute of Bioeconomy Research) is a national research institute working to develop knowledge and solutions in bioeconomy, sustainable resource management, and climate adaptation, with expertise in forestry, agriculture, and environmental research.

NIBIO conducts gas measurements and data analysis in Woodstore and will contribute to quality assurance of the reports and data from the project.

Site Service Norway

Site Service Norway has extensive experience and expertise in gas measurements within the landfill industry. They have conducted gas measurements and prepared several measurement reports for Woodstore.

Puro.Earth

Puro.earth is a leading platform for carbon removal and has developed its own standard for carbon removal, along with a methodology for biomass storage – TBS (Terrestrial Storage of Biomass). Woodstore falls under the TBS category. Puro specializes in verified solutions for measurable permanent carbon sequestration and uses independent third parties to ensure the quality of carbon credit providers.

Puro.earth will certify the first carbon credits from Woodstore.

Income Potential for the Forester

Our philosophy behind Woodstore is to develop a carbon capture method that is simple and profitable.

This enables other foresters to start carbon capture and get more value from their forestry operations. Globally, we achieve increased carbon capture; locally, we create greater economic value.

Carbon credits are becoming an important tool in the fight against climate change. They provide an economic incentive for carbon capture and storage. A carbon storage method with proven high quality and permanence will generate higher-priced carbon credits, and market forecasts indicate that prices will rise in the coming years. This aligns with the increasing importance of the efforts needed to meet climate goals. Woodstore is a method with the potential to qualify for high-quality carbon credits (long-term storage for thousands of years). Depending on how such carbon credits are priced in the future, Woodstore could become more valuable to the forest owner than the timber itself.

OTHER STAKEHOLDERS

Stakeholders using CSWB methods

Although the idea behind Woodstore is new to many, Sylva is not the only pioneer. The companies listed below use different methods of carbon storage, but all are examples of CSBW methods. Many around the world have recognized the potential of the CSBW approach and how effective such climate measures can be. Read more about them here:

Biomass stored moist underground

Biomass stored dry above ground